Construction

How to Automate Construction Project Data Processing to Mitigate Predictive Analytics Challenges

November 05, 2025 • 110 Views • 36 min read

Tetiana Stoyko

CTO & Co-Founder

Predictive analytics in construction promises smarter decisions, fewer risks, and better project outcomes.

Yet, many companies struggle to unlock their potential. Why? Their construction project data is scattered, inconsistent, and manually handled.

Despite massive investments in data analytics in construction, most predictive models still rely on outdated inputs.

Excel spreadsheets, disconnected field reports, and inconsistent site updates create blind spots that make predictions unreliable.

To fix that, companies must first fix how data flows.

Automation in construction data processing is no longer optional. It’s the backbone of predictive accuracy, operational efficiency, and cost transparency.

So, how can construction firms automate their data pipelines to overcome analytics challenges and finally make their predictive systems work?

Key Takeaways

- Manual construction data workflows create errors, delays, and inconsistencies that make predictive analytics unreliable

- Excel spreadsheets and disconnected field reports create data silos that prevent real-time insights

- Automated data pipelines (APIs, ETL, cloud storage) connect existing tools into unified, real-time data systems

- Machine learning and anomaly detection enable early warning systems for cost overruns, delays, and safety issues

- Automation reduces reporting time by 20-40% and improves cost forecasting accuracy by up to 25%

- Real-time data transforms predictive tools from dashboards into actionable decision engines

- Implementation requires connecting data sources, standardizing formats, centralizing storage, and building dashboards

- Data governance, security compliance, and change management are critical success factors

- Automation is essential, not optional, for construction companies to compete on predictive analytics

The Pitfalls of Manual Construction Data Collection

In construction, data has quietly become one of the most valuable yet underutilized assets.

Every day, teams generate enormous volumes of information — from field inspections and material tracking to procurement logs and scheduling updates.

Yet for many organizations, this data remains trapped in manual workflows and disconnected systems.

Instead of smooth, automated data flow, most companies rely on spreadsheets, shared drives, and human entry.

Field supervisors submit reports by email, accountants manually retype figures into ERP systems, and analysts spend hours cleaning inconsistent spreadsheets.

The result? Critical construction project data becomes fragmented, outdated, and error-prone before it even reaches your analytics tools.

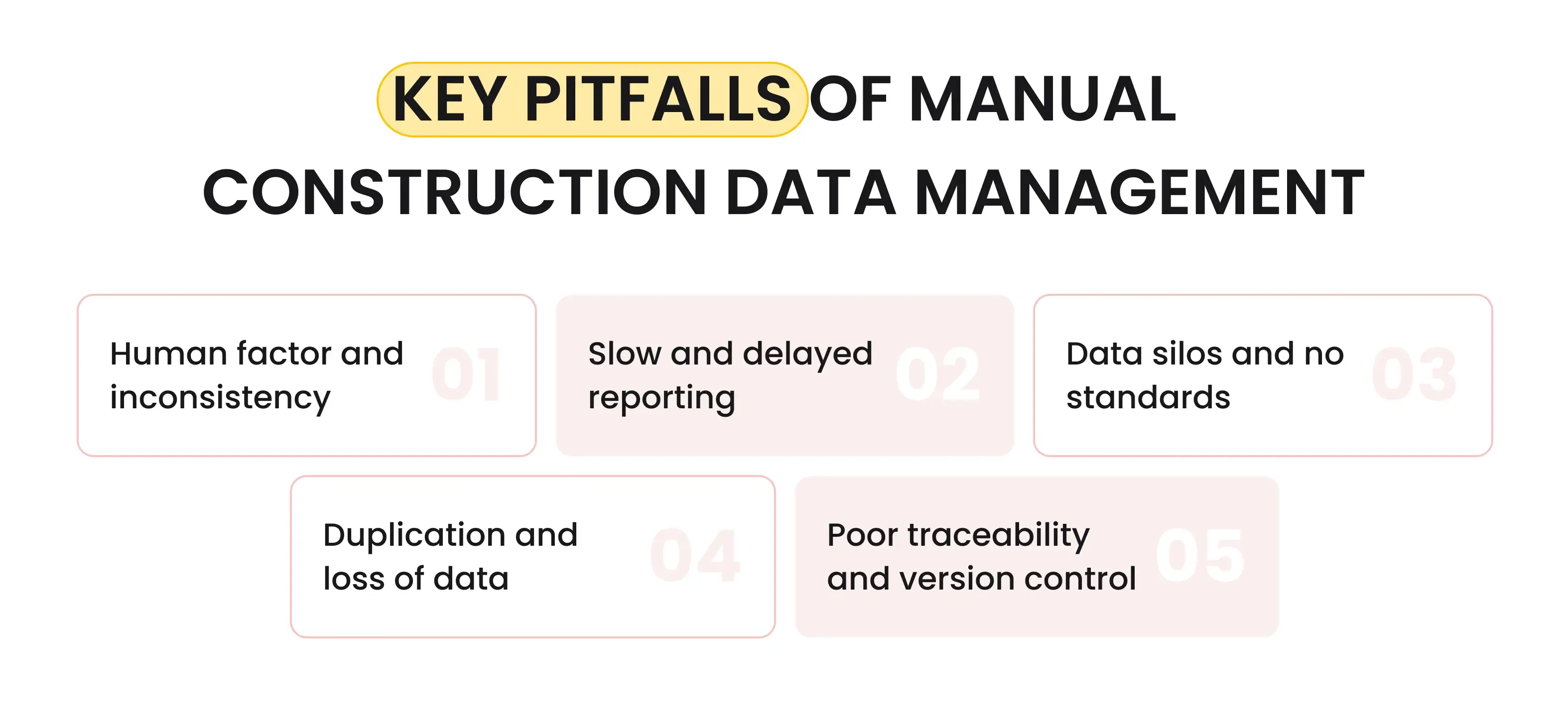

Manual construction data collection creates more than just inefficiency. It builds structural barriers to insight. Let’s break down what typically goes wrong:

-

Human Error and Inconsistency Every manual input is an opportunity for mistakes — incorrect figures, mismatched units, missing timestamps, or miscategorized expenses. Across large projects, these inconsistencies multiply and distort future analysis.

-

Slow and Delayed Reporting When updates are sent weekly instead of instantly, your “current” data can already be days old. This time lag makes it nearly impossible to maintain accurate forecasts or perform timely construction data analysis.

-

Data Silos and Non-Standard Formats One team might log data in cubic meters while another uses square feet. Some rely on legacy Excel templates, others on PDFs. Without automated normalization, predictive systems can’t interpret these variations, leading to unreliable outcomes.

-

Data Duplication and Loss Without centralized storage, the exact cost item may appear twice, or worse, disappear entirely. These duplicates and gaps directly impact construction cost data tracking and budgeting accuracy.

-

Poor Traceability and Version Control Manual systems lack an audit trail, making it difficult to confirm when data was last updated or by whom. That weakens accountability and makes predictive insights less trustworthy.

When your foundation is built on fragmented and inconsistent information, every layer above, including reporting, analytics, and forecasting, becomes unstable.

The solution?

One of the most efficient methods is leveraging AI business automation services, which use artificial intelligence or similar innovative software to streamline operations and processes.

How It Affects Predictive Analytics in Construction Outcomes

Predictive analytics in construction is only as good as the data feeding it.

The most advanced AI model or dashboard will fail if the underlying information is flawed, incomplete, or delayed.

Manual data collection directly undermines the reliability and responsiveness of these systems.

Consider a few real-world scenarios:

- If labor productivity data is inconsistently logged across sites, predictive models will miscalculate staffing needs, leading to idle teams or unexpected overtime costs.

- When construction cost data arrives late, forecasting tools can’t identify budget overruns in time to take corrective action.

- If site performance updates lag behind actual events, risk models will miss early warning signs of delays or safety issues.

This disconnect between real-world conditions and analytical insight creates a dangerous illusion:

Executives believe they have accurate predictions when, in reality, their models are running on outdated or incomplete data.

That’s why many businesses investing in data analytics in construction struggle to see tangible ROI.

The algorithms aren’t the issue — the data pipeline is. When data is inconsistent, even high-end predictive tools produce false confidence: impressive visuals, but unreliable intelligence.

IT solutions for the construction industry address this issue at its root.

By automatically standardizing construction project data capture and formats, streamlined operations ensure that every metric is accurate, time-stamped, and integrated across departments.

The result? Reliable, real-time visibility and predictions you can actually trust.

Ultimately, a digital overhaul isn’t just about technology adoption. It is about reclaiming control over your information flow.

Automating construction data processing transforms chaos into clarity, allowing predictive analytics to function as it was always meant to: a decision-making compass, not a rearview mirror.

What Is Automated Construction Data Processing?

After years of struggling with fragmented spreadsheets and manual updates, the construction industry is now moving toward something more innovative — automated data processing.

If traditional systems depend on humans to collect, clean, and move data, automation removes that bottleneck.

Streamlined data processing captures information directly from the source, standardizes it in real time, and sends it where it’s needed, instantly and accurately.

In simple terms, automated construction data processing means replacing repetitive human data work with connected, intelligent systems that do it faster and without error.

Instead of relying on separate tools and templates, every stream of construction project data flows through a unified pipeline.

Data automation doesn’t just digitize this process, but synchronizes it.

Such systems integrate people, platforms, and equipment into a single, continuous data ecosystem, keeping predictive models constantly updated with real-world inputs.

Core Technologies Behind Construction Project Data Automation

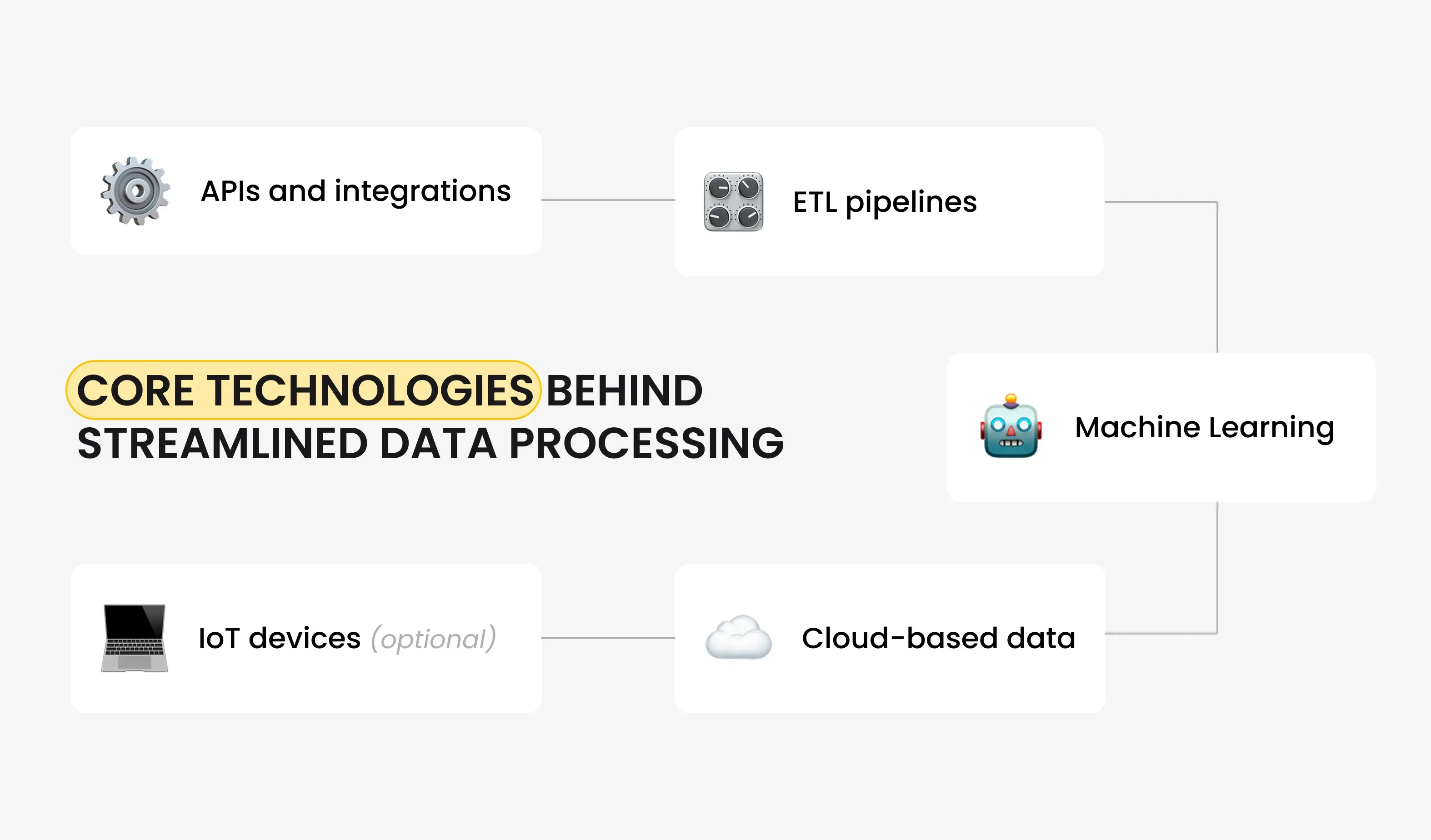

Behind the scenes, this ecosystem runs on a blend of modern technologies working together:

-

APIs and Integrations: Middleware connects existing tools — like BIM 360, Procore, Oracle Primavera, or ERP software — so all systems share the same data foundation.

-

ETL Pipelines (Extract, Transform, Load): Automated scripts collect and clean raw information, eliminating duplicate entries and formatting inconsistencies.

-

Machine Learning Algorithms: These detect anomalies, predict missing values, and even learn patterns that enhance construction data analysis accuracy.

-

Cloud-Based Data Lakes: Scalable, secure repositories store all project information, ensuring accessibility and performance across departments and locations.

-

IoT Devices and Drones (optional): Sensors monitor concrete curing, equipment usage, temperature, and site safety in real time, feeding data automatically into your system.

Together, these components form a digital backbone that ensures a frictionless construction data collection process and continuously informs your predictive analytics in construction models.

Automation eliminates the noise. No more chasing down spreadsheets or reconciling mismatched reports.

Every new field update or sensor reading instantly strengthens the predictive engine driving your business decisions.

Real-Time Construction Data and Speed

Speed is the difference between being reactive and being proactive.

In construction, where conditions change by the hour, delays in information can cost thousands, sometimes millions.

That’s why real-time construction data is essential to achieving accurate, responsive forecasting.

Imagine not guessing, but knowing that:

- Your equipment utilization dropped 15% this morning,

- Your procurement order will miss delivery by two days,

- Or labor productivity fell below the norm on a specific site.

That’s the level of visibility automation delivers.

When data analytics in construction operates in real time, predictive systems become more than dashboards, but decision engines.

They can warn managers before overruns occur, adjust schedules automatically, or trigger alerts when conditions deviate from historical norms.

The payoff is enormous: higher accuracy, faster insights, and far less time wasted cleaning data.

Instead of spending hours verifying numbers, teams can finally focus on what those numbers mean.

Automation doesn’t just improve efficiency, it transforms the entire value of your data. It’s the bridge between collecting information and actually making it useful.

Linking Construction Data Analysis with Predictive Accuracy

Automation is only the foundation.

What truly drives transformation is how automation fuels predictive accuracy.

Once your construction data starts flowing in real time, the next critical step is turning that data into something meaningful.

That’s where construction data analysis and predictive modeling intersect.

In predictive analytics, accuracy isn’t a byproduct. It is everything.

And accuracy depends on one thing above all else: the quality and consistency of your construction project data.

Even minor variations in input can cause significant deviations in output.

Automation helps fix that by enforcing consistency and ensuring every data point is complete, verified, and contextualized before it reaches your analytical systems.

High-quality data and a seamless, automated workflow allow companies to set up and scale new, streamlined operations using innovative technologies.

For instance, using AI forecasting to prevent material delays in construction.

The Role of Quality Construction Project Data

Predictive models thrive on context.

If your data lacks granularity, the resulting predictions will be too generic to act upon.

For instance, if material deliveries or weather events aren’t tied to specific time frames or project locations, the predictive model will not account for them, resulting in a less accurate forecast.

Clean, standardized construction project data gives your predictive tools the situational awareness they need.

Automation ensures that:

- Every data entry is formatted the same way across all sources.

- Each record includes timestamps, geolocation, and project identifiers.

- Data validation rules prevent incomplete or contradictory inputs.

This level of standardization not only improves the reliability of reports but also dramatically enhances predictive analytics in construction by making it easier for algorithms to find patterns across projects and time periods.

For example, when cost, weather, and labor data are aligned on the same timeline, your system can start detecting correlations, such as how a 2-day weather delay typically impacts cost variance on high-rise projects.

That’s insight you can act on before it happens again.

How AI-Powered Tools Improve Data Analytics in Construction

Artificial intelligence now plays a transformative role in modern data analytics in construction. Beyond simply crunching numbers, AI-powered tools learn from patterns, identify risks, and improve over time.

They bridge the gap between raw automation and real intelligence. Here’s how:

-

Anomaly Detection: Machine learning models flag unusual cost spikes, schedule deviations, or underperforming subcontractors before they escalate.

-

Predictive Modeling: AI correlates historical and real-time construction data to forecast budget overruns, equipment downtime, or material shortages.

-

Data Enrichment: Automated systems can merge external data sources — such as weather forecasts or supply chain updates — to increase context depth.

-

Continuous Learning: Every completed project refines the model, making predictions more accurate for the next one.

What makes this combination powerful is that it turns construction data analysis into a living system instead of a static report.

The more you automate and feed it data, the more intelligent and reliable your predictive tools become.

In short, automation provides predictive analytics with clean fuel, and AI turns that fuel into valuable insights.

Together, they transform guesswork into foresight, helping you act before risks turn into losses.

Bringing It All Together

When predictive analytics runs on high-quality, automated data, executives gain more than visibility — they gain control.

They can adjust resource allocations instantly, fine-tune budgets in real time, and simulate multiple project outcomes before making significant decisions.

That’s the new gold standard of predictive analytics in construction — not just knowing what’s happening, but anticipating what’s next.

And it all starts with the integrity of your construction project data and the intelligence of your construction data analytics.

Cost Efficiency and Risk Reduction Through Smart Automation

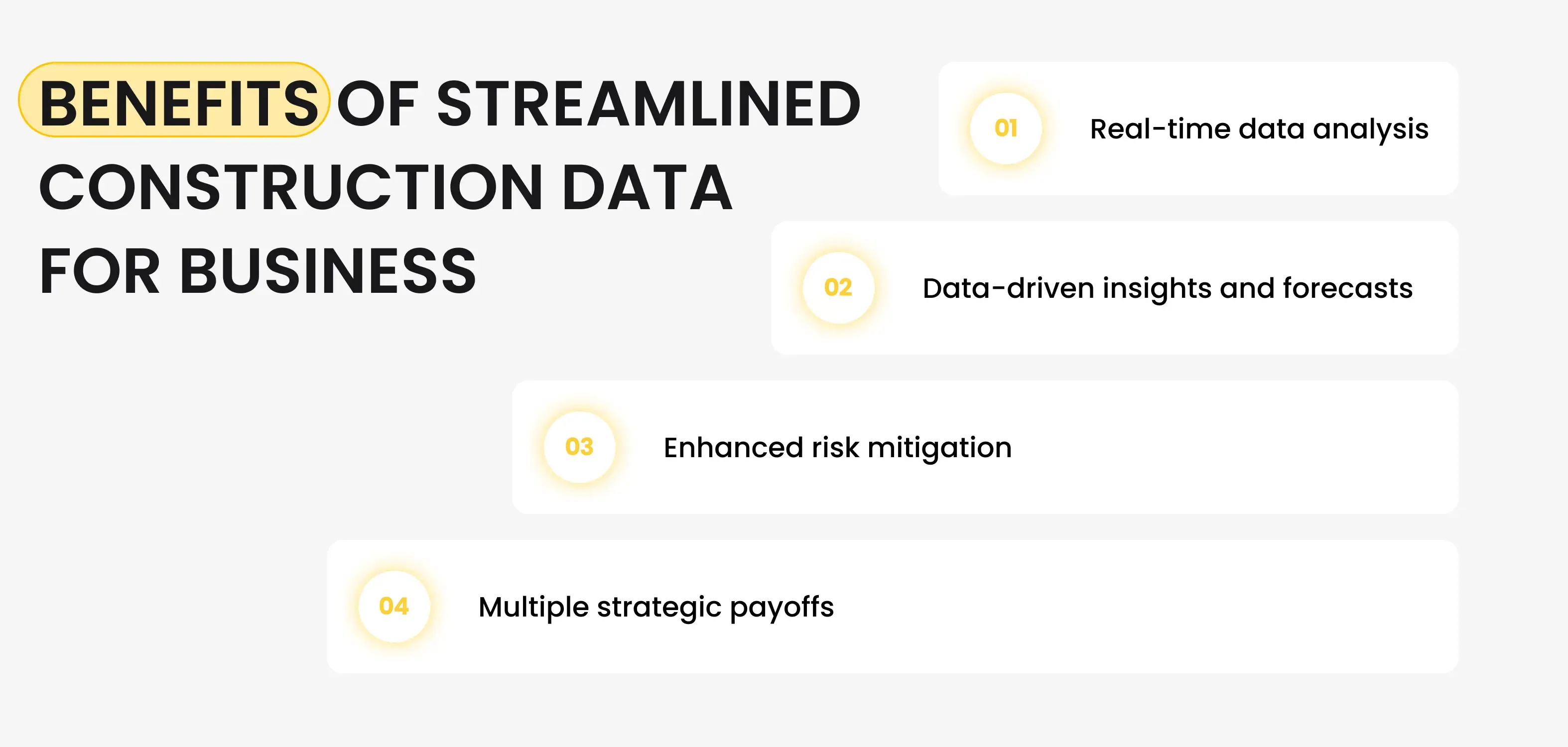

One of the most precise and most immediate payoffs of automation in construction data processing is cost efficiency.

When your data flow is automated, every number becomes traceable, up to date, and available for instant analysis.

This directly impacts how well you manage budgets, allocate resources, and forecast financial performance.

In traditional workflows, cost reports often lag behind real activity by days or even weeks. By the time teams realize they’re over budget, it’s already too late to fix.

Automated systems eliminate that delay.

They collect construction cost data in real time, automatically reconciling it with project progress and flagging anomalies before they snowball into serious financial issues.

Construction data collection automation turns cost control from a backward-looking audit into a forward-looking management tool.

Analyzing Construction Cost Data Without Delays

Let’s consider a practical scenario.

A project’s procurement system logs every material order and delivery.

Meanwhile, the finance system tracks invoices and payments, and the scheduling platform records project progress.

In a manual setup, these systems operate separately — so reconciling the numbers becomes a tedious, error-prone task.

With automation, data synchronization happens continuously.

Each purchase order, invoice, and site update is linked through shared identifiers. As a result:

- Project managers identify cost overruns as they occur, rather than after month-end reports.

- Financial officers can monitor construction cost data trends in real time, adjusting forecasts immediately.

- Executives gain a unified financial dashboard that reflects the actual, up-to-the-minute state of every project.

This level of visibility ensures that construction data analysis becomes a strategic asset, not a clerical process.

It minimizes manual reconciliation work, shortens reporting cycles, and enables predictive models to operate on real data rather than historical snapshots.

The outcome? You spot inefficiencies earlier, allocate budgets more effectively, and prevent waste before it happens.

Predictive Insights from Historical and Real-Time Construction Data

Intelligent automation also bridges the gap between hindsight and foresight.

By merging historical and real-time construction data, predictive systems can forecast both risks and opportunities.

Here’s how this combination works:

-

Historical Data: Reveals long-term trends. For example, which suppliers consistently deliver late, or which phases typically exceed labor budgets.

-

Real-Time Data: Shows the immediate impact of those variables as they unfold, such as this week’s productivity drop or current weather disruptions.

When connected, these datasets form a living model that evolves daily.

Predictive algorithms then use this continuously updated information to forecast upcoming challenges — from equipment failures and material shortages to budget deviations and schedule delays.

This is where predictive analytics in construction becomes truly actionable. Rather than generating static reports, it delivers dynamic, data-driven guidance.

It tells you not only what is happening but also why, and what to do next.

Data Automation as a Risk Mitigation Strategy

Beyond efficiency, automation also reduces project risk.

Errors in cost reporting, inconsistent updates, and delayed information all create uncertainty, leading to financial losses.

When construction project data flows automatically and transparently across all stakeholders, that uncertainty disappears.

For example:

- Automated safety monitoring using IoT sensors can detect anomalies before they lead to accidents.

- Integrated procurement systems can flag supplier delays before they affect schedules.

- Predictive models can estimate the financial impact of a potential risk and suggest mitigation steps in advance.

By eliminating human delays and data fragmentation, process automation transforms construction data analytics into a proactive shield against risk.

It enables leaders to move from reacting to problems to anticipating them — and acting with confidence.

The Strategic Payoff of Streamlined Data

From a business standpoint, the return on investment is undeniable.

Judging from our experience, companies that automate their construction data collection and analysis typically see:

- 20–40% reduction in reporting time

- Up to 25% improvement in cost forecasting accuracy

- Significant drops in unplanned expenses and rework

This translates into faster project delivery, improved profit margins, and more predictable outcomes.

Most importantly, it frees executives from endless data verification, allowing them to focus on growth, innovation, and strategic decisions.

Automation doesn’t just cut costs. It creates a self-correcting, insight-driven operation.

Every action taken today enriches your predictive intelligence for tomorrow.

Imagine this: your next project runs 15% under budget and finishes three weeks early — not by luck, but because predictive models warned you about risks before they happened.

Sounds impossible? It’s not — it’s just automated.

Steps to Automate Your Construction Project Data Pipeline

From Data Collection to Predictive Modeling

A well-structured automation process starts with making construction data work. It also follows these key stages:

- Automate Data Collection: Connect all input sources (IoT, BIM, ERP, spreadsheets).

- Data Cleaning & Transformation: Standardize and verify construction project data formats.

- Centralized Storage: Create a unified repository for all project records.

- Integration with Predictive Engines: Feed clean data into machine learning or BI tools.

- Visualization: Build dashboards for real-time construction data analysis.

Each step creates a foundation for accuracy and scalability, enabling predictive systems to deliver reliable insights across all project stages.

Integration with Existing Construction Platforms

Automation doesn’t mean starting from scratch. Most systems integrate seamlessly with tools like Procore, Autodesk BIM 360, or SAP ERP.

This ensures that all departments, particularly finance, procurement, and site management, share a common version of the truth.

The outcome is faster collaboration and unified performance tracking.

Overcoming the Common Challenges

Every transformation comes with friction.

Automating construction project data is not just a technical upgrade. It is an operational shift that affects how teams capture, share, and trust information.

Before the benefits of automation fully take hold, construction companies often face a few predictable hurdles.

The list of the most common and influential challenges includes:

- Data silos and fragmentation

- Security, compliance, and ownership

- Data quality and trust issues

- Resistance to change and cultural barriers

- Data governance and continuous oversight

The good news? Each one has a clear and proven path forward.

Data Silos and Fragmentation

The biggest obstacle to practical construction data analysis is fragmentation.

When each department, from design to finance to field operations, uses its own tools and data formats, it creates silos that make holistic insights impossible.

A project manager might rely on a scheduling app, while the finance team uses an ERP, and procurement tracks costs in Excel.

The result is a patchwork of disconnected information, with no single version of the truth.

This fragmentation directly undermines predictive analytics in construction, because predictive models depend on complete, cross-functional datasets.

When those datasets live in isolation, even the most advanced algorithms can’t make accurate predictions.

How to overcome it:

- Centralize through Integration: Leverage APIs and middleware to integrate all systems, including BIM, ERP, scheduling, and field reporting, into a unified ecosystem.

- Adopt a Common Data Environment (CDE): A CDE serves as a single repository for all project data, ensuring teams work from a single source.

- Define Ownership: Assign data stewards in each department responsible for maintaining consistency and governance.

Once silos are broken, data flows naturally, enabling true automation and reliable predictive modeling.

Security, Compliance, and Ownership in Construction Data Analysis

When automating data flows, many executives ask the same question:

“How do we ensure security and compliance while data moves automatically across systems?”

It’s a critical concern — and a legitimate one.

Modern construction projects handle sensitive data, including contract details, employee information, and financial transactions.

Automating these flows means rigorously controlling privacy, integrity, and access.

To secure construction project data, organizations should implement multi-layered protection:

- Encryption at Rest and in Transit: Ensures that data remains secure whether stored in a cloud data lake or transmitted between systems.

- Role-Based Access Controls: Limit who can view or modify sensitive datasets to prevent unauthorized changes.

- Regulatory Compliance: Adhere to standards like GDPR (in the EU), CCPA (in the US), and ISO 27001 (for information security).

- Audit Trails: Maintain complete visibility over every transaction and modification, ensuring accountability and governance.

Automating construction data collection doesn’t have to mean losing control — in fact, it often strengthens control.

With the right security frameworks, every data point is traceable, permissioned, and compliant.

Best practice: Partner with technology vendors or software development experts, such as Incora Software.

We design automation architectures with built-in compliance and security protocols from day one.

Data Quality and Trust Issues

Even when automation is in place, poor input quality can still create skepticism among teams.

If site supervisors or accountants doubt the accuracy of dashboards, they’ll revert to manual methods — undermining adoption.

The solution lies in transparency and validation.

Automation should include mechanisms to verify, flag, and communicate data status. For example:

- Validation rules that catch inconsistent inputs

- AI-assisted quality checks that highlight probable errors

- Data lineage tracking, so users can see where each number came from

When stakeholders understand and trust the process, adoption becomes organic.

This trust turns data analytics in construction from an IT project into a company-wide mindset shift.

Resistance to Change and Cultural Barriers

Not every challenge is technical. Often, the most complex barriers are human.

Teams that have relied on spreadsheets for years may be hesitant to embrace automation.

They fear loss of control or simply don’t see the immediate benefit. This resistance can quietly derail even the best-designed automation projects.

To overcome it:

- Communicate Value Early: Demonstrate how automation simplifies daily tasks, such as faster reporting, fewer errors, and less double entry.

- Provide Training and Support: Equip teams with practical guidance on using new tools and understanding their impact.

- Celebrate Early Wins: Share success stories internally, like cutting reporting time from days to hours, to build momentum.

Automation works best when it’s not perceived as a “tech initiative” but as a business enabler.

When people see how it improves their own workflow, adoption accelerates naturally.

Data Governance and Continuous Oversight

As data volumes grow, governance becomes non-negotiable.

Without a clear framework, even automated systems can produce inconsistencies over time.

Effective governance involves:

- Defining clear roles for data ownership and stewardship

- Establishing standard operating procedures for data entry, review, and updates

- Conducting regular audits to verify data quality and process compliance

Governance isn’t bureaucracy — it’s quality assurance for your digital transformation.

It ensures that your predictive analytics in construction models remain accurate, that your construction data analysis remains credible, and that your organization maintains regulatory readiness at every stage.

Turning Challenges into Competitive Advantages with Incora

Every obstacle on the automation journey, such as silos, security, quality, or adoption, can become a differentiator when handled strategically.

Companies that address these challenges head-on don’t just automate their workflows; they elevate their entire decision-making culture.

Once data becomes unified, secure, and trusted, predictive analytics in construction stops being a buzzword and becomes a measurable performance driver, cutting waste, improving safety, and unlocking foresight across operations. And that’s where true digital maturity begins.

Automation is more than a digital trend — it’s the new operating model for construction.

By eliminating manual bottlenecks, enhancing data analytics in construction, and improving the quality of construction project data, automation empowers predictive tools to deliver what they promise: foresight, efficiency, and profit.

The companies that automate today will set the performance benchmarks of tomorrow.

What’s your impression after reading this?

Love it!

17

Valuable

10

Exciting

3

Unsatisfied

1

FAQ

Let us address your doubts and clarify key points from the article for better understanding.

Why is manual construction data collection a problem for predictive analytics?

Manual workflows introduce errors, delays, data silos, duplicates, and poor traceability—making predictions unreliable and leading to missed budget overruns and safety risks.

What is automated construction data processing?

Automated systems replace manual work by capturing data from all sources, standardizing it in real time, and distributing it through a unified pipeline using APIs, ETL, machine learning, and cloud storage.

What are the core technologies enabling data automation?

APIs and integrations, ETL pipelines, machine learning algorithms, cloud-based data lakes, and IoT devices/drones that monitor equipment, safety, and site conditions in real time.

How does real-time data improve predictive analytics?

Real-time data transforms predictions from static dashboards into dynamic decision engines, enabling teams to identify issues immediately—like dropping equipment utilization or missed procurement deadlines—and adjust proactively.

What measurable benefits does automation deliver?

20–40% reduction in reporting time, up to 25% improvement in cost forecasting accuracy, and significant drops in unplanned expenses and rework.

What are the biggest challenges to implementing automation?

Data silos, security and compliance concerns, data quality skepticism, resistance to change, and data governance complexity.

How can construction companies overcome resistance to automation adoption?

Communicate value early, provide hands-on training and support, and celebrate early wins like faster reporting to help teams view automation as a workflow enabler rather than a burden.

YOU MAY ALSO LIKE

Construction

AI Compliance Agent for Construction: Automating HSE and Regulatory Compliance

Management Systems

Construction Project Management Software for Small Business: Complete Guide

Construction

AI Shift Scheduling for Construction: Is This the Future of HR and Payroll?

Construction

From 10 to 2 Hours: How Conversational AI Agents Transform Construction Report Generation

Construction

How AI Negotiation Agents Improve Construction Procurement [And Why Do You Need It]

Construction,

Real Estate

How Construction Workflow Management Software Helps to Reduce Costs and Boost Efficiency?

Construction

How Integrated BOQ Software Bridges the Gap Between Construction Departments

Construction

How to Build a Custom Software for Hard and Soft Construction Budget Control

Construction

How to Create a Procore Alternative Software for a Construction Business

Construction

How to Deal With Weaknesses of Construction Financial Management Software?

Real Estate

How to Select the Right Construction Management Software for Your Business

Construction

Investing in the Right Construction Reporting Software: Features That Make a Difference

Construction

Is Voice Technology Worth the Investment for Construction Firms?

Construction

Overcoming Integration Challenges: Making Construction Data Work Together with BI Tools

Management Systems

Simple Construction Software for Construction Planning: Case Study

Construction

The Complete Guide to AI Construction Document Review for Project Management

Let’s talk!

This site uses cookies to improve your user experience. Read our Privacy Policy

Accept

Share this article