Construction

How Does AI Forecasting in Construction Prevent Material Delays?

October 03, 2025 • 121 Views • 27 min read

Tetiana Stoyko

CTO & Co-Founder

AI-driven construction forecasting is one of the fastest-growing solutions in this industry. Material delays cost the industry billions annually, with over 70% of construction firms experiencing significant project delays due to material availability issues. The average construction project now runs 46.8 days behind schedule, with only 8.5% of large projects finishing on time and on budget.

In this challenging environment, AI forecasting emerges as a transformative solution that shifts construction companies from reactive material management to proactive data-driven operations. Thanks to sophisticated algorithms like Prophet and Temporal Fusion Transformers (TFT), as well as their alternatives, construction businesses can predict material shortages weeks in advance. This can help them to optimize procurement cycles and eliminate the costly delays that have plagued the industry for decades.

But what is AI-driven forecasting in construction management, and how does it help to prevent material delays?

What Is AI Forecasting in Construction?

At its core, AI forecasting utilizes predictive analytics, machine learning algorithms, and time series models to anticipate future material needs with unprecedented accuracy.

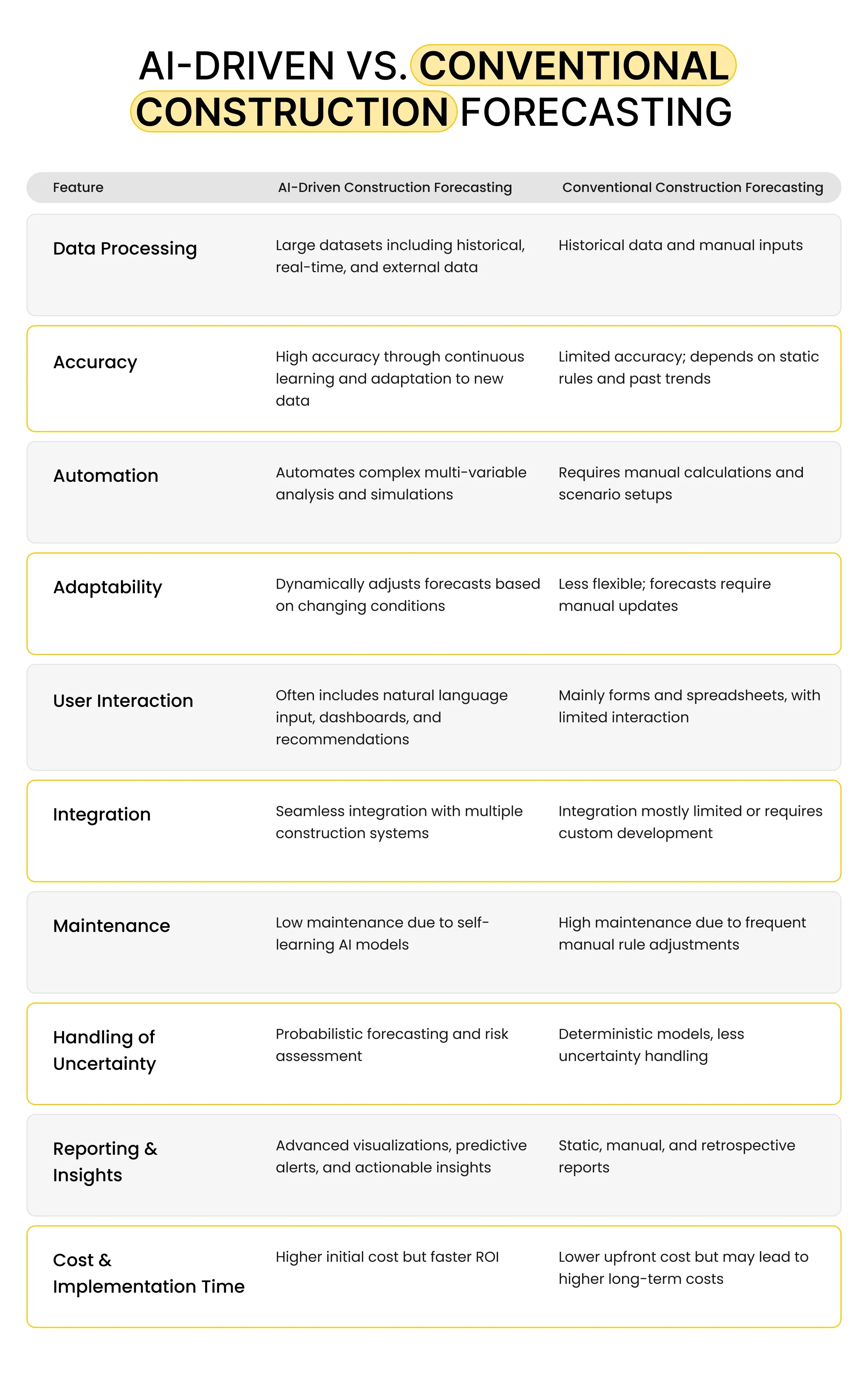

The difference between conventional methods and AI-driven systems is clear:

- Conventional methods rely on manual estimations or simple historical averages.

- AI forecasting systems continuously analyze vast datasets encompassing historical usage patterns, project timelines, weather conditions, supplier performance metrics, and market trends.

As a result, AI solutions for material forecasting provide much more complex and comprehensive analysis, based on multiple factors and data sources. This allows managers to access more detailed and accurate insights, making decision-making easier and faster.

Furthermore, the variety of software-based construction management solutions offers limitless potential for future scaling and growth. Thanks to machine learning, such systems can continually improve during operation. Besides, AI platforms can be scaled even more thanks to multiple data sources and IoT solutions.

Long story short, AI-based construction forecasting solutions provide your teams with advanced insights, allowing them to make more accurate predictions and estimations. It is highly beneficial in dealing with the most common inventory and asset management challenges.

Common Inventory and Asset Management Challenges in Construction

Construction inventory management shares some common challenges with other industries. However, it also faces unique issues, creating a perfect storm of inefficiencies that directly impact project success and profitability. The short list of the most typical such problems includes:

- Stockouts leading to project delays.

- Overstock is tying up capital.

- Manual tracking of materials across multiple sites.

- Errors in predicting future material needs.

- Inefficient procurement cycles.

Stockouts and Project Delays

Stockouts represent one of the most devastating challenges facing construction firms, with cascading effects that extend far beyond simple material shortages. When critical materials are unavailable at crucial moments, entire work crews become idle, resulting in cascading effects throughout project schedules that can delay subsequent phases by weeks.

The financial impact of stockouts extends beyond labor costs. Material shortages prompt emergency procurement at premium prices, often resulting in costs that are 20-50% higher than planned purchases. Emergency orders disrupt supplier relationships and compromise quality standards, as rushed procurement processes bypass routine vetting procedures.

What is the most effective way to resolve the stockout and related issues? The best way to do so is to prevent stockouts in advance by applying the best practices for predictive inventory management. This includes regular material monitoring and planning, as well as placing new orders in advance. However, such a management process requires a significant amount of time, effort, and attention to detail. Moreover, it requires a specific set of skills for prediction and pattern recognition.

Otherwise, poor predictive inventory management can lead to another issue - overstocking.

Overstocking

Overstocking ties up capital that could generate returns elsewhere in the business, with carrying costs reaching 10-20% of inventory value annually. These costs encompass storage fees, insurance, taxes, handling expenses, and the significant risk of material deterioration or obsolescence.

Unused materials contribute to construction waste, piling up in landfills and straining natural resources while providing zero return on investment. Storage complexities multiply overstock costs in construction environments.

Unlike centralized warehouses, construction materials often require on-site storage in challenging conditions, exposing inventory to theft, weather damage, and deterioration. Security costs for protecting high-value materials at remote construction sites add another layer of expense, making excess inventory particularly burdensome.

Solution? To find the most efficient ways of managing materials, which will help to prevent overstock and stockouts. Yet, all such solutions highly depend on data and up-to-date information. This can be an issue due to the next challenge - manual material tracking.

Manual Material Tracking and Management

Manual inventory tracking represents a fundamental weakness in construction operations, introducing human error while creating dangerous information lags. This inefficiency diverts skilled labor from productive construction activities to administrative tasks that add limited value.

Paper-based systems and basic spreadsheets remain surprisingly common across the construction industry. This creates information silos that prevent real-time visibility across multiple job sites. Manual tracking cannot deliver the real-time visibility essential for effective resource allocation, leading to order duplications, material misplacements, and frequent stockouts.

Not to mention how much more challenging it becomes for bigger companies with multi-site projects. Manual communication between sites relies on phone calls and emails that create delays and increase the risk of miscommunication.

Fortunately, IT services for construction offer countless software-based solutions for automated material tracking, including systems for forecasting in construction management. However, it may be challenging to find a perfect offer that meets all your needs and demands, especially when it comes to conventional construction forecasting solutions.

Errors in Material Forecasting

Traditional forecasting methods struggle with the dynamic conditions inherent in construction projects. Manual estimation processes are also prone to human error, with a single miscalculation or missed line item potentially damaging entire material orders.

Project complexity factors make accurate forecasting particularly challenging. A larger number of factors to consider increases the likelihood of discrepancies between projected and actual material needs.

Price volatility adds another layer of complexity to the forecasting process. Construction material prices fluctuate rapidly due to disruptions in the global supply chain. Combined, these factors make it difficult to predict not just material quantities but also the optimal timing for purchases to minimize costs while ensuring availability.

The best and most effective approach to modern construction forecasting is to find and integrate software for process automation. Such instruments can also streamline operations and help address inefficient procurement cycles.

If you struggle to find a suitable and affordable technological solution, consider contacting a reliable construction software development company. Such specialists can advise you and lead your integration project, addressing all business needs and requirements.

Inefficient Procurement Cycles

Accurate and latest data is everything for effective construction forecasting and procurement.

Traditional procurement processes are notoriously slow to respond to changing project needs. This commonly results in emergency orders at premium prices that devastate project budgets. Also, manual procurement approval chains create bottlenecks that prevent a rapid response to emerging material needs.

Apart from scraping data and structuring it, automated systems for construction procurement can behave more autonomously. For example, some modern procurement virtual assistants can place orders or bets on specified marketplaces. Additionally, they can establish communication pipelines to notify all parties and clarify all necessary details.

Long story short, such software can create a seamless procurement environment and material forecasting.

How Can a Forecast Agent Improve Construction Inventory Management?

The modern IT field offers numerous solutions, carefully tailored and simplified to ensure the best user experience. SaaS solutions and affordable AI API Integrations allow all businesses to achieve higher forecasting efficiency.

Once again, AI forecast agents are among the most popular innovative solutions in the construction field. The reason is simple: they can easily cover all the foregoing challenges if implemented correctly. Probably the most popular services include:

- Predicting material demand accurately using Prophet/TFT models

- Automatically generating purchase requests when stock is low

- Prioritizing orders based on project timelines and urgency

- Optimizing storage and reducing waste

Material Forecasting using Prophet/TFT models

Frankly, you don’t have to integrate full-fledged virtual assistants to benefit from automated material forecasting. In fact, there are at least a few popular algorithms that are distributed as SaaS solutions by other software companies. Additionally, it is possible to test and integrate pre-trained models that offer surprising accuracy out of the box.

For instance, Prophet models excel at handling the complex seasonal patterns and irregular trends that characterize demand for construction materials. The model's decomposable time series structure separates demand into trend, seasonality, and holiday effects.

This enables construction managers to understand the underlying drivers of material consumption. Automatic changepoint detection identifies when demand patterns shift due to project phase transitions or external factors, adjusting predictions accordingly without manual intervention.

Prophet's robust handling of missing data and outliers proves invaluable in construction environments where data collection frequently encounters interruptions. Its Bayesian approach to curve-fitting maintains prediction accuracy even with incomplete datasets, ensuring reliable forecasts despite challenging data conditions.

At the same time, Temporal Fusion Transformers (TFT) provide sophisticated multi-horizon forecasting capabilities that process diverse input types simultaneously. TFT models integrate static covariates (project specifications, site characteristics), known future inputs (planned construction phases, scheduled activities), and unknown time-varying inputs (weather patterns, supplier disruptions) to generate comprehensive demand predictions.

The attention mechanism automatically identifies which variables most strongly influence material needs, providing interpretable insights that construction managers can act upon with confidence.

Multi-step prediction capabilities enable construction teams to forecast material requirements across different time horizons: daily predictions for immediate procurement decisions, weekly forecasts for supplier coordination, and monthly projections for strategic planning. This temporal flexibility allows construction managers to optimize different aspects of material management simultaneously.

Yet, predictive inventory management and material forecasting are not the only reasons to consider integrating artificial intelligence.

Automated Purchase Requests

AI business automation is one of the most significant benefits of these solutions. A variety of existing virtual assistants can streamline multiple processes, ranging from simple data scraping and processing to more complex tasks, such as placing purchase requests in advance.

AI agents continuously monitor real-time inventory levels against dynamic demand predictions. They can also trigger automated purchase orders when stock levels fall below intelligently calculated reorder points.

Many modern software systems for construction procurement offer static reorder services. This feature automatically places orders if a certain predefined inventory level is reached. Thanks to the ability to track inventory status in real-time, AI-driven solutions can adjust reorder points based on current demand patterns and various other factors. This helps to ensure more optimal inventory levels without manual intervention and prevents potential stockouts more efficiently.

AI systems can simultaneously request quotes from multiple suppliers, analyze responses based on predefined criteria, and even execute orders automatically when conditions meet established parameters. This automation eliminates procurement delays while ensuring competitive pricing and reliable delivery.

Orders Prioritization

Apart from real-time inventory tracking and placing orders, AI-driven construction forecasting can perform order prioritization. Based on various factors and information integrated from management systems and scheduling software, artificial intelligence can automatically prioritize orders based on their potential impact on overall project completion.

Critical path analysis ensures that materials supporting time-sensitive activities receive procurement priority, even if they're not the most expensive or largest volume items. Risk assessment algorithms evaluate the consequences of delayed deliveries, considering not just immediate schedule impacts but also cascade effects on subsequent activities.

It is possible to train AI not only for forecasting in construction management, but also for other services or operations. For instance, with proper training, you can adjust such models to supplier capacity coordination.

Thus, AI negotiation agents will work with multiple vendors simultaneously, ensuring that high-priority materials receive preferential treatment during periods of peak demand. The system can automatically negotiate delivery schedules, request expedited processing, or identify alternative suppliers when primary vendors are unable to meet priority requirements.

Storage Optimization

Thanks to the advanced algorithms and data-driven decision-making, virtual assistants can become a perfect solution for storage optimization, helping to prevent overstocking and stockouts.

Just-in-time delivery optimization is one of the most powerful waste reduction capabilities of such systems. They can calculate optimal delivery schedules that minimize on-site storage requirements while ensuring material availability precisely when needed. Perishable materials, such as concrete, adhesives, and specialized chemicals, benefit particularly from such coordination.

Pattern-seeking ability and access to planning datasets help to achieve incredible forecasting precision. Machine learning algorithms analyze historical consumption patterns, project specifications, and construction progress to predict material needs.

Advanced algorithms continuously refine multiple optimization parameters based on actual performance outcomes, ensuring the system improves over time through operational learning.

Real-World Applications in Construction

One of the best news is that AI for construction forecasting is not a concept. In fact, numerous examples of such technologies are already in use in the industry today. Leading construction companies worldwide are demonstrating the transformative power of AI forecasting. These solutions are used to achieve measurable results and innovative implementations that demonstrate the technology's practical value.

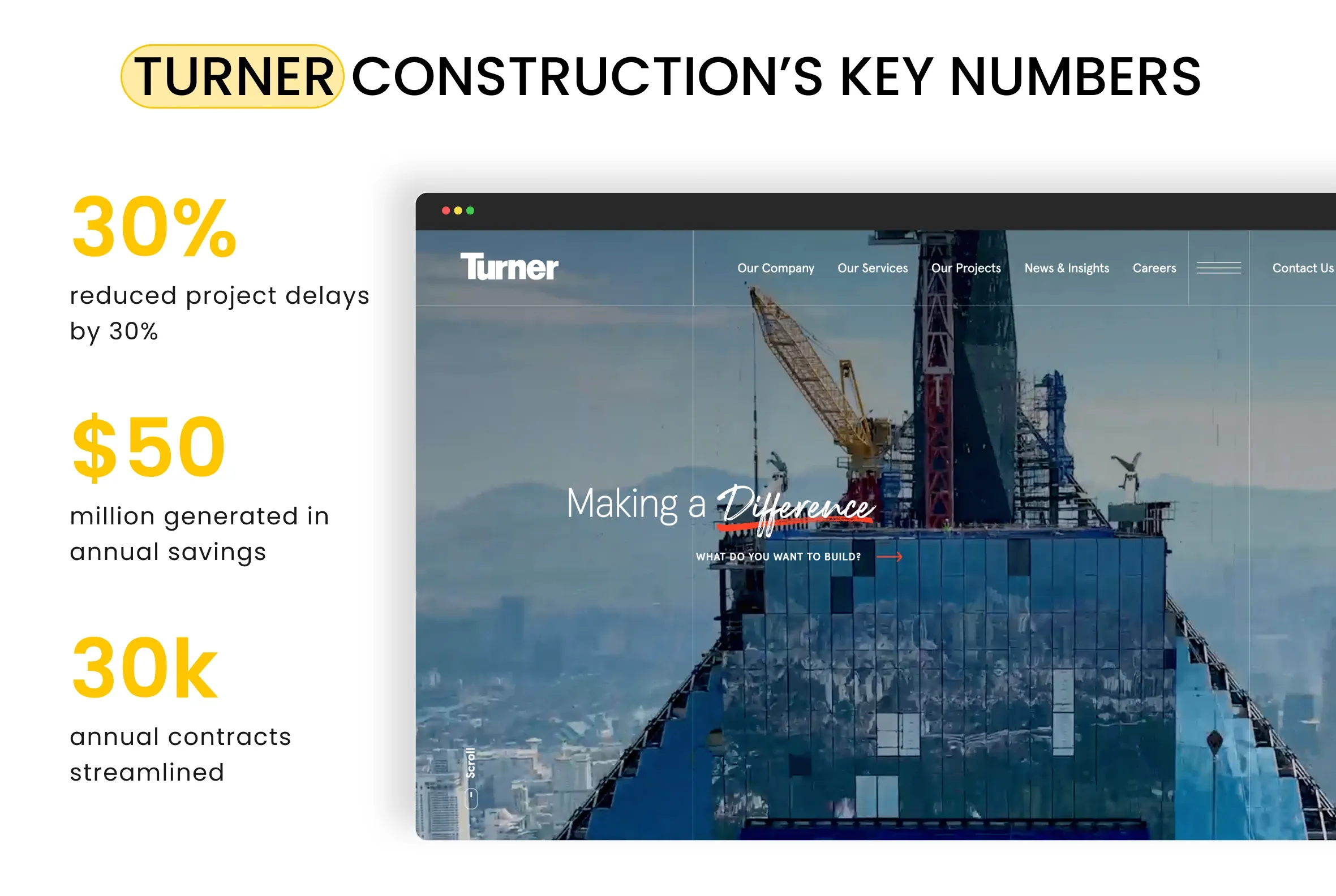

Turner Construction’s AI for Forecasting

One of the latest, most prominent examples of such transformation is Turner Construction. According to their statement, the AI integration shows excellent results.

The company reduced project delays by 30% and generated over $50 million in annual savings. Apart from using AI for intelligent project management, the company has adopted AI-powered contract generation, which streamlines the 30,000 annual contracts required for primary construction operations.

Their predictive scheduling capability analyzes historical project data, current site conditions, weather patterns, supplier reliability, and resource availability to create dynamic schedules that adapt continuously in response to changing project circumstances.

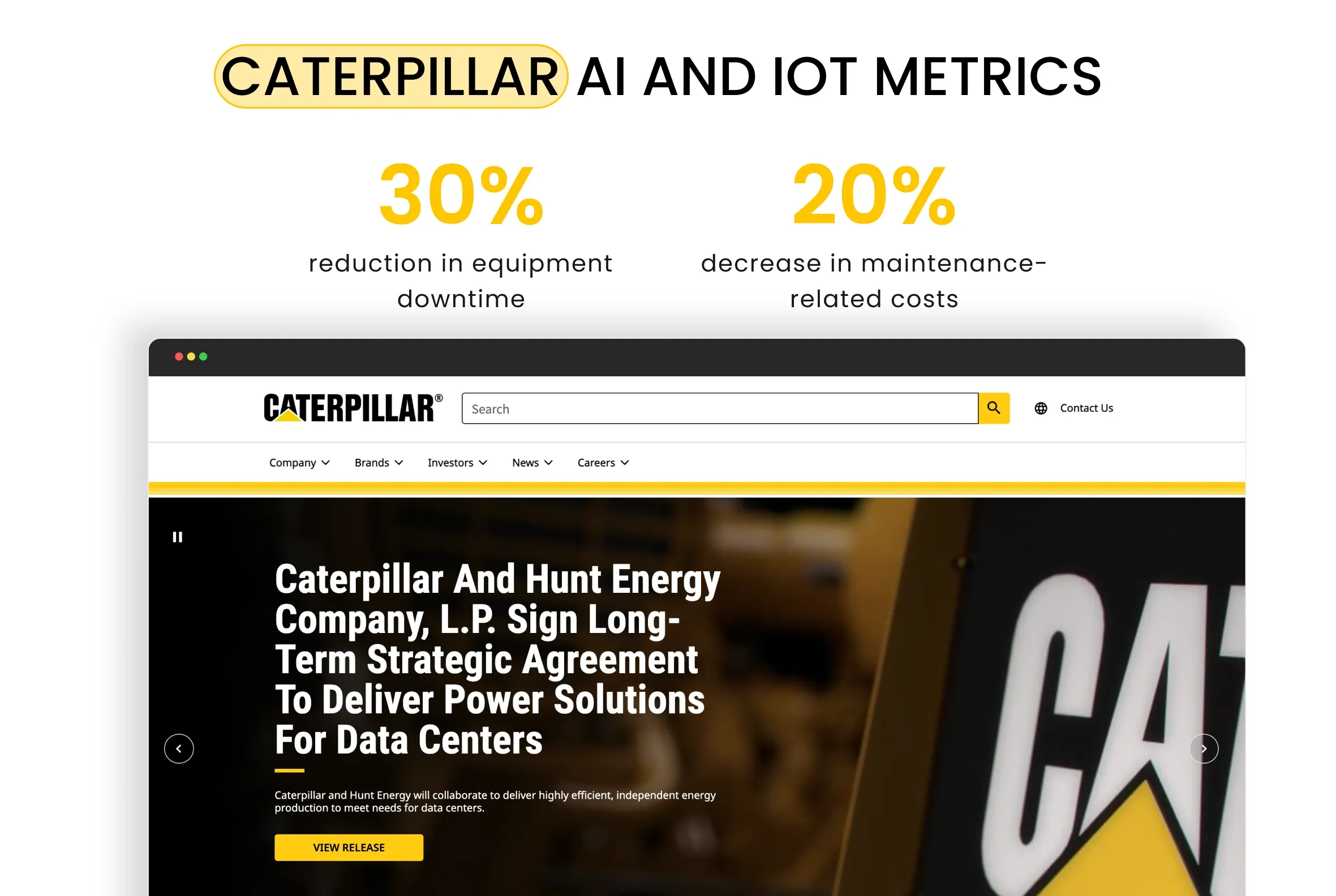

Caterpillar AI and IoT

Caterpillar, as a leader in the construction and machinery industries, has taken a step further by combining artificial intelligence and Internet of Things solutions.

As a result, apart from an intelligent assistant for advisory and process automation, Caterpillar linked its construction equipment to the core management systems. This data helps to predict maintenance needs and prevent unexpected breakdowns.

This proactive approach has resulted in a 30% reduction in unplanned equipment downtime and a 20% decrease in maintenance-related costs. When equipment operates more reliably, material delivery schedules become more predictable, reducing the need for emergency material orders.

Autodesk AI-Enhanced Management Platform

Another example of successful AI adoption is presented by Autodesk, a tech giant that offers numerous SaaS solutions for management, including industry-specific platforms.

This AI-enhanced construction management platform showcases integrated forecasting improvements in project coordination and management. The platform uses NLP models to parse progress reports and worker feedback.

At the same time, built-in predictive analytics assesses the probability of various project outcomes. Users report 20% improvements in project delivery time and significantly enhanced coordination across multidisciplinary teams. The system's ability to integrate BIM data with real-time progress monitoring allows precise material demand forecasting, aligned with actual construction progress.

Future of AI Construction Forecasting

The real-life cases of AI construction forecasting are currently limited. However, it doesn’t mean that such integration is not worth the investment.

In fact, the future of these technologies promises unprecedented potential. These solutions exemplify excellent data analysis, automation, and self-sustainability. Apart from predictive inventory management, artificial intelligence can be applied to numerous related fields and tasks.

Besides, the overall accessibility and affordability of various AI models make it an almost perfect technology for the industry. Long story short, all types of construction businesses can benefit from AI-based services, ranging from basic data management and categorization to material forecasting and streamlined procurement.

Summing up all the above, the construction industry stands at the threshold of an AI-driven transformation that will make material delays a relic of the past, delivering superior project outcomes while contributing to operational excellence. The primary challenge is finding a suitable tech partner capable of providing the expected results.

Why Choose Incora for AI Forecasting in Construction?

The evidence speaks volumes: AI forecasting delivers measurable results that directly impact your bottom line.

Don’t delay your business transformation, and become one of the industry leaders with Incora Software. By partnering with our team, you will receive experienced and valuable guidance throughout each stage of AI integration.

Our developers have proven experience in the construction industry and tech expertise in AI implementation. To explore our latest case studies and learn more about the terms of our cooperation, please drop us a line, and we will take it from there.

We will gladly listen to your needs and ideas to find the most efficient way to bring them to life!

What’s your impression after reading this?

Love it!

33

Valuable

20

Exciting

6

Unsatisfied

1

FAQ

Let us address your doubts and clarify key points from the article for better understanding.

What is AI forecasting in construction?

AI forecasting in construction uses machine learning and predictive analytics to anticipate material needs with high accuracy. By analyzing data like project timelines, weather, supplier performance, and market trends, it helps companies prevent stockouts, reduce overstocking, and optimize procurement cycles - keeping projects on schedule and within budget.

Are AI forecasting agents cost-effective for construction companies?

Yes, AI forecasting agents are highly cost-effective for construction companies. They reduce costly stockouts, prevent overstocking, and streamline procurement, cutting expenses tied to delays and emergency orders. By improving efficiency and accuracy, AI solutions deliver measurable savings while boosting project timelines, making them a smart long-term investment.

Can AI forecasting integrate with existing construction management systems?

Yes, AI forecasting can seamlessly integrate with existing construction management systems. Modern AI tools connect with project management software, procurement platforms, and IoT devices to deliver real-time insights. This integration enhances visibility, automates workflows, and ensures smoother operations without requiring companies to overhaul their current systems.

What types of materials can a Forecast Agent manage?

A Forecast Agent can manage a wide range of construction materials, including concrete, steel, lumber, adhesives, chemicals, and other project-specific supplies. By tracking demand patterns and delivery schedules, it ensures timely availability, reduces waste, and optimizes storage - covering both perishable materials and long-term inventory.

YOU MAY ALSO LIKE

Management Systems

Construction Project Management Software for Small Business: Complete Guide

Construction

How AI Negotiation Agents Improve Construction Procurement [And Why Do You Need It]

Construction,

Real Estate

How Construction Workflow Management Software Helps to Reduce Costs and Boost Efficiency?

Construction

How Integrated BOQ Software Bridges the Gap Between Construction Departments

Construction

How to Create a Procore Alternative Software for a Construction Business

Construction

How to Deal With Weaknesses of Construction Financial Management Software?

Real Estate

How to Select the Right Construction Management Software for Your Business

Construction

Investing in the Right Construction Reporting Software: Features That Make a Difference

Construction

Is Voice Technology Worth the Investment for Construction Firms?

Construction

Overcoming Integration Challenges: Making Construction Data Work Together with BI Tools

Management Systems

Simple Construction Software for Construction Planning: Case Study

Let's talk!

This site uses cookies to improve your user experience. Read our Privacy Policy

Accept

Share this article