Supply Chain

Why You Should Invest in Supply Chain Automation for the Future of Your Business

April 18, 2025 • 117 Views • 21 min read

Tetiana Stoyko

CTO & Co-Founder

Supply chain automation is one of the industry's most recent trends. Logistics and supply chain companies have many reasons for adopting software solutions. Still, streamlined processes are one of the most influential and beneficial services offered by software systems.

Such businesses rely heavily on information about ongoing processes and operations. Logistics companies can't scale their services and commonly struggle with many issues without a clear and transparent awareness of what is happening within the supply chain.

This need for clarity is also a common reason why such companies are tempted to avoid innovations and radical changes: Why would you touch something that works?

On the one hand, such an approach is justified and can be easily understood. However, it also limits your business's prosperity and scalability options. Even though we can’t suggest risk-free supply chain automation solutions, we can name a few arguments on how such risks can pay off.

Besides, working with an experienced supply chain software development company can significantly reduce the potential risks while delivering highly beneficial logistics management software.

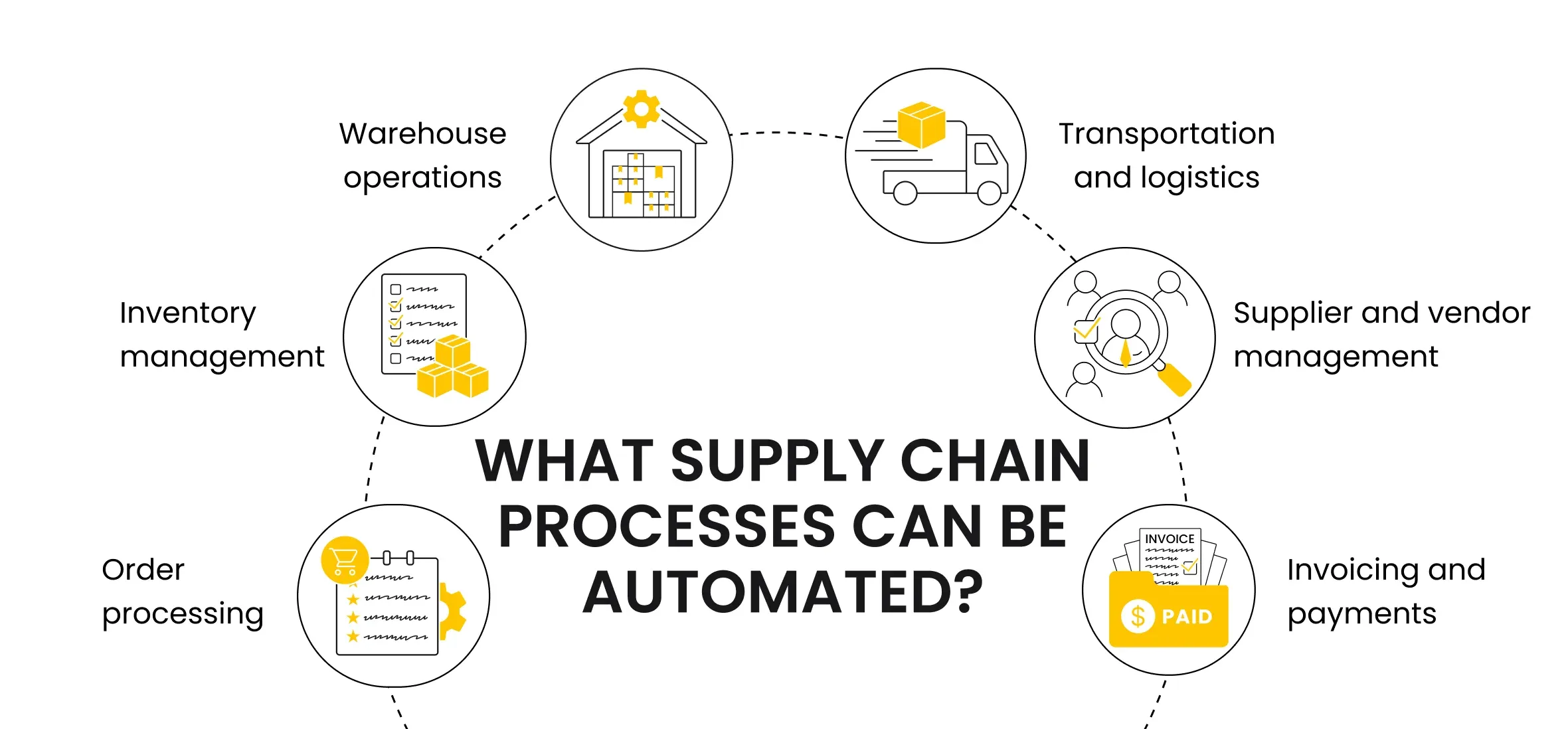

What Supply Chain Processes Can Be Automated?

First of all, we have to admit that not all operations within a supply chain can be automated. Such industries are very fragile and demand engaging specialists to manage and monitor different processes. Still, we can make a short list of software solutions capable of streamlining some supply chain tasks like:

- Order processing

- Inventory management

- Warehouse operations

- Transportation and logistics

- Supplier and vendor management

- Invoicing and payments

Order Processing

One of the first options that comes to mind is order processing automation.

Depending on what you expect and need, there are many approaches and possible solutions to achieve the best results. For instance, some companies already provide completely automated ordering, where the system accepts the customer’s order and fills in all related forms, updates statuses, and shares required information like the type of order, products or services, address for the delivery, builds routes, and simply notifies assigned specialists.

Alternatively, it is possible to set up a similar data-sharing pipeline, leaving the final decision-making to a designated employee. In this case, the system still processes orders and performs all the foregoing actions but waits for approval from your in-house experts.

Therefore, you can boost the overall efficiency and speed of processing incoming orders while avoiding potential mistakes and keeping the supply chain manageable by letting your employees check the correctness of filled data and decide whether to proceed to packaging and delivery, edit, or cancel the order.

Inventory Management

Inventory management is probably one of the supply chain parts most suited for automation. It includes countless operations and tasks that require constant employee engagement if they are not streamlined. Besides, most such operations are highly repetitive and suitable for templating.

So, why should your employees spend their time manually performing tasks such as sharing data, filling in forms, checking the inventory status, looking for different items, etc.? Streamlining these processes is highly beneficial for your business efficiency and also suggests the possibility of creating a seamless transition from ordering to delivery.

Automated inventory management allows you to redirect your resources to more critical or complex tasks and automates related operations like warehouse management and streamlined product restocking.

Once again, to keep the system manageable and avoid potential mistakes, it is possible to leave the final decision-making to a warehouse or inventory management team, automating the data gathering and visualization to provide them with more accurate and detailed information about the status of various products, what can be restocked, what expired, etc.

Warehouse Operations

Many routine warehouse operations can also be streamlined. However, at this point, some clarification must be done. There are two main approaches to warehouse operations automation:

- Software-based optimization, which offers different solutions and instruments to streamline data-related processes, such as item status updates, warehouse workload analysis, and advanced inventory management systems.

- Hardware-driven automation suggests that companies use drones, robotics, autonomous vehicles, and other similar tools to perform physical tasks such as transportation, sorting, etc. However, software automation is a primary task: it can work without integrating or operating machinery and can handle only data-related processes and software-based functions. At the same time, physical or hardware optimization can’t work without related software solutions and systems.

Thus, if you are considering any of the foregoing warehouse management automation options, you should always start by creating a reliable software system that corresponds with your goals and provides the requested features or services.

Transportation and Logistics

Long story short, all the foregoing automation solutions already boost transportation and logistics efficiency:

- Streamlined order processing cuts the time to prepare the product for delivery.

- Automated inventory management additionally speeds up parcel preparations and ensures that in-demand goods are always available in storage.

- Optimized warehouse management operations ensure the correctness of the filled information and cover the final preparations for the delivery.

Nevertheless, automation in supply chain management can also cover some logistics and transportation practices. For instance, you can optimize routing and streamline data sharing with freight forwarders.

If you want to go even further, you can implement an advanced transportation management system capable of choosing drivers and transportation agents or orchestrating loads.

Supplier and Vendor Management

In addition to advanced TMS automation, your logistics business can benefit from streamlined supplier and vendor management.

Apart from covering the core operations within the supply chain, finding reliable vendors who provide cheaper or higher-quality services is crucial. Therefore, logistics companies can significantly reduce their expenses or offer new products and goods to their clients.

Cooperating with new suppliers is complex and always requires the engagement of communication specialists. However, finding new potential partners usually consists of surfing the b2b platforms and looking for contacts on the Internet. AI automation services or even simpler software-driven solutions like data scrapers and scripts can easily streamline data-gathering operations.

Despite their simplicity, such tasks are highly resource-intensive when performed manually. Even if you shouldn’t automate communication with new suppliers, prioritizing a personalized approach and streamlined contact data gathering helps to speed up the process of setting new contacts and agreements.

Invoicing and Payments

Finally, invoicing and payment processing automation is a nice and efficient solution to boost your supply chain business and ensure better performance. Like other data-dependent operations, they are an excellent fit for software automation. Otherwise, they will require a lot of attention from employees, making them perform repetitive and routine tasks manually.

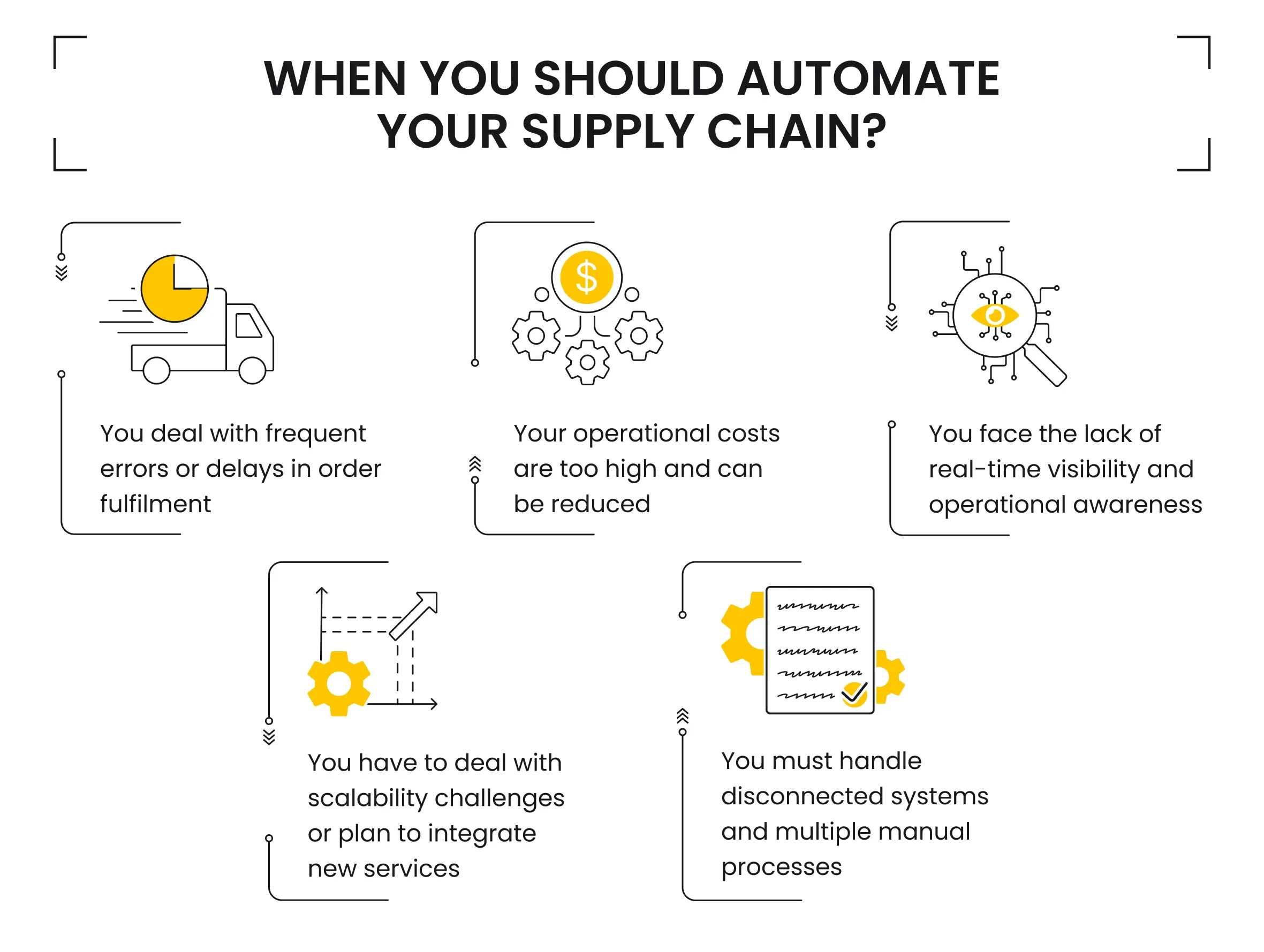

When It’s Time to Automate Your Supply Chain

Knowing what you can streamline in your supply chain is great, but learning when it’s time to consider supply chain automation is even better. Long story short, here is a short list of red flags that signify you should consider such solutions:

- Frequent errors or delays in order fulfillment

- High operational costs

- Lack of real-time visibility

- Scalability challenges

- Disconnected systems and manual processes

Frequent Errors or Delays in Order Fulfillment

One of the core features and benefits of automating logistics and supply chain operations is the possibility of eliminating mistakes and ensuring seamless processes under the hood.

This can bring much value to companies that commonly struggle with errors or want to reduce delay rates, especially regarding order fulfillment. It includes not only placing and processing a customer’s order but also suggests all order-related operations up to its successful delivery.

Therefore, if your business commonly faces frequent errors and order delays, you must consider applying some of the best automation practices for the transportation and logistics industry.

High Operational Costs

Another great benefit of streamlined supply chain operations is cost-efficiency.

This suggests cutting expenses or other resources on manual tasks like filling forms, inventory management, or warehouse optimization and monitoring. Additionally, a seamless automated supply chain helps reduce risks and expenses for other operations and issues like delays or delivery mistakes, as well as speeds up the order-delivery process.

Lack of Real-Time Visibility

Real-time visibility and awareness of ongoing processes are common issues. Ensuring real-time visibility and statistics can’t be done without automation because this feature is data-driven and requires constant updates.

If performed manually, it is not “real-time” and commonly provides outdated information. It is typically used to generalize the status updates of different processes or pinpoint significant changes.

Real-time visibility, on the other hand, provides your team with the most recent information and helps enhance management practices. It allows quick response, issue resolution, and simplifies monitoring the progress of specific projects and tasks if they are high priorities, etc.

Apart from improving management practices and problem-solving, real-time visibility is also a powerful tool for planning and analysis.

Scalability Challenges

Frankly, we believe that automation in supply chain management is a must-have solution for all companies that plan to scale their services or software. Otherwise, if a scaling company refuses to automate supply chain operations, it must increase its spending and scale the in-house team to cover new features and services.

Moreover, managing more processes also brings new challenges, such as a higher error rate, performance issues, or additional manual tasks.

Alternatively, streamlined supply chains are suitable for further scaling, providing businesses more convenience while maintaining operational efficiency.

Disconnected Systems and Manual Processes

As was mentioned above, many manual processes can be easily streamlined. However, SCM automation is also a possible solution for handling disconnected systems.

It is not a secret that many businesses use third-party software solutions to cover some elements or operations. However, many such systems can’t be linked with each other directly by default. There are two possible solutions to such scenarios:

- Manually updating data by employees, which can be a very resource-intensive process.

- Creating a data sharing pipeline using custom transportation management app development services, or even simpler projects, depending on the context of your case, your business needs, and project specifics.

Thanks to automated data sharing between different applications, your team can achieve high performance and avoid manually rewriting data, focusing on more critical tasks.

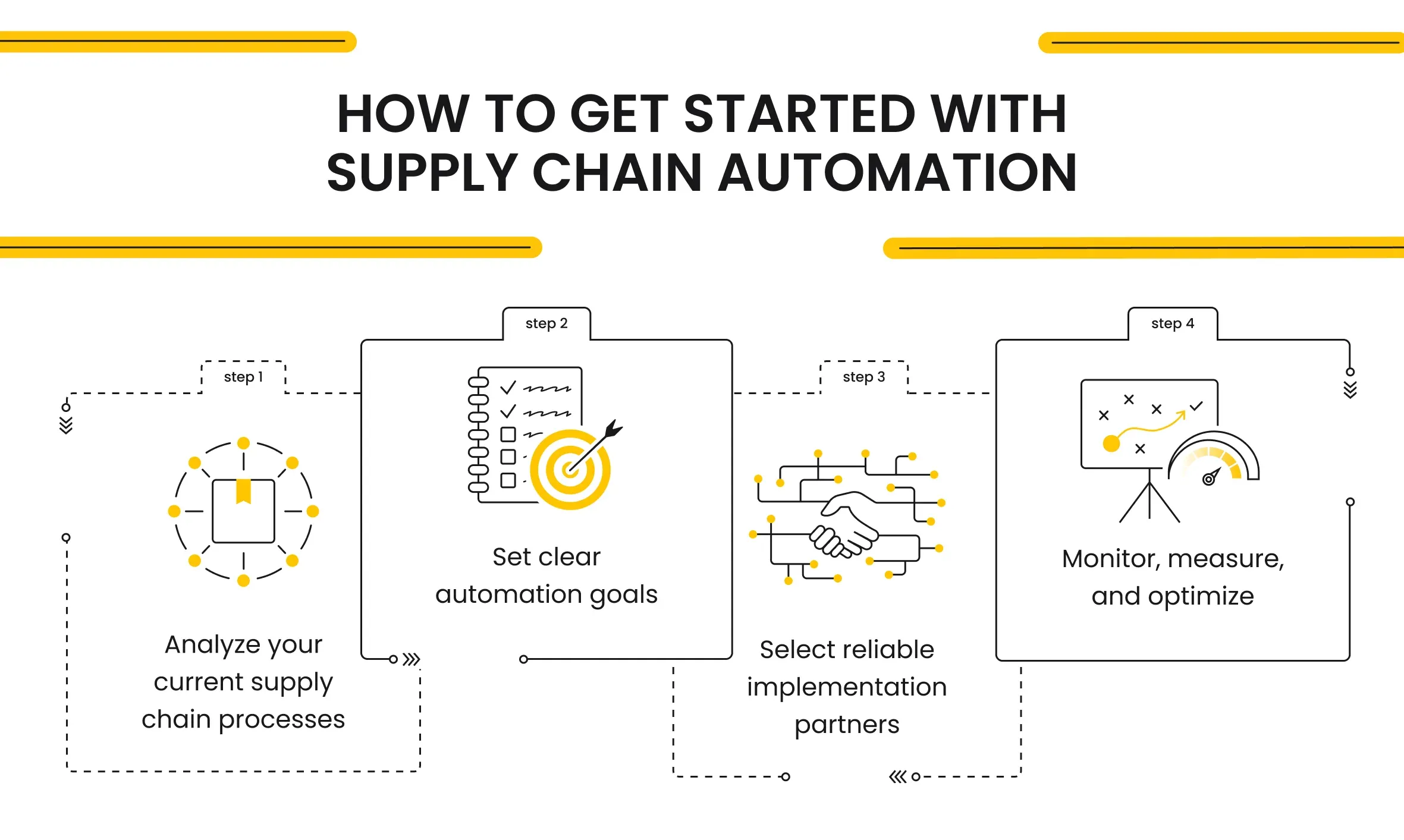

How to Get Started with Supply Chain Automation

Finally, let’s discuss the best way to start your supply chain automation project. The short list of actions before starting such automation:

- Analyze your current supply chain processes

- Set clear automation goals

- Select reliable implementation partners

- Monitor, measure, and optimize

Analyze Your Current Supply Chain Processes

The first step always assumes analysis. In terms of SCM automation, you must examine and sort your current processes. This suggests not only creating a complete list of such operations but also examining each one, looking for weaknesses or bottlenecks, considering potential solutions, and considering what can be improved.

With this information, you can proceed to the following stages and start planning a future supply chain automation project.

Set Clear Automation Goals

After learning more about your supply operations and finding potential software improvement options, you must clarify your goals for such projects.

It is essential to see the bigger picture and know what to improve. Still, even if you can enhance something, it doesn’t mean you should proceed immediately. Simply put, you must clarify your core needs and goals for the current moment and prioritize future actions to meet these goals.

Each project has imperfections and options to scale and improve. Therefore, instead of creating flawless software, you should first focus on achieving your core business goals and needs. After implementing all essential features and services, you can start polishing and improving other aspects of your software or business.

The same is true for supply chain automation: despite being able to streamline many different unrelated processes, you should set up clear expectations.

Select Reliable Implementation Partners

After you have prioritized your goals, planned the software project, and defined the core operations to automate, you should find a reliable development team capable of delivering the expected result and meeting your expectations.

To find a matching company, you should pay attention to their:

- Reviews on B2B platforms like Clutch or GoodFirms

- Previous case studies and other experiences

- Expertise in software technologies and development tools

On top of that, we recommend paying attention to industries your potential tech partner has worked with. Finding a software team familiar with supply chains and logistics can bring a lot of additional value to your business:

Thanks to their expertise, such niche-experienced developers will not only deliver a product with the demanded quality and functionality but also advise you on other software practices and solutions, helping you avoid mistakes or risks.

When you create a list of the most suitable candidates for a tech partnership, you should interview them, consider their prices, discuss your ideas, and listen to their suggestions. When you choose the best offer and sign agreements, you can finally start your supply chain automation project.

Monitor, Measure, and Optimize

Eventually, when you delegate software development to a technological partner, you still should participate in the project.

In a nutshell, you have to observe and track the project's progress, test the efficiency and overall impact of automation in supply chain management, and decide on potential disputes.

If you did everything right in the previous stages, there will be almost no issues during this phase, except for a few minor decisions and potential issues that can be easily solved.

Why Investing in Automation Is a Long-Term Business Strategy

Summing up all the above, supply chain automation is a highly profitable and beneficial solution that can help your business thrive and grow, saving costs and efforts, while prioritizing more important tasks over repetitive manual operations.

Nevertheless, we should also admit that such automation solutions are more of a long-term business strategy. All the potential benefits and advantages we described before can be seen over time after a successful automation implementation.

If you are looking for an immediate solution to save costs or speed up ongoing logistics and transportation operations, you might be disappointed. Adjusting the existing system and integrating streamlined operations into your logistics business is not a cheap or fast task. It still requires initial investments, as well as dedication and expertise from the software team.

Finally, even after you streamline some operations in your supply chain, it will take some time to check if everything works correctly and to improve or optimize them for better efficiency and accuracy.

Either way, we highly recommend talking to experienced software developers before initiating any such automation projects. You should know all the pros and cons, which can vary depending on your context.

What’s your impression after reading this?

Love it!

1

Valuable

1

Exciting

1

Unsatisfied

1

FAQ

Let us address your doubts and clarify key points from the article for better understanding.

What technologies do you used in supply chain automation?

In supply chain automation, we use technologies like AI and machine learning for demand forecasting, IoT for real-time tracking, RFID for inventory management, robotics for warehouse automation, and blockchain for secure and transparent transactions. ERP systems and cloud-based platforms also help streamline operations and improve visibility across the supply chain.

How long does it take to implement supply chain automation?

The time to implement supply chain automation varies based on the complexity of the system, but it typically takes 3 to 12 months. Smaller projects may take a few months, while larger, enterprise-wide implementations can take up to a year or more, especially if integration with existing systems is required.

Is automation in supply chain expensive to implement?

Yes, supply chain automation can be expensive to implement initially due to costs for technology, software, and integration. However, it often leads to long-term savings through increased efficiency, reduced errors, and lower labor costs, making it a worthwhile investment for many businesses.

What challenges should I expect during automation implementation?

Common challenges during automation implementation include integration with existing systems, high upfront costs, employee resistance to change, data quality issues, and the need for skilled personnel. Proper planning, training, and change management can help address these challenges effectively.

YOU MAY ALSO LIKE

Supply Chain

Transportation Management Application Development: Best Practices for Success

Let’s talk!

This site uses cookies to improve your user experience. Read our Privacy Policy

Accept

Share this article